ㆍTest target: Support up to 62" of sample size for LED BLU, CCFL BLU, LCD module, OLED module, PDP, etc

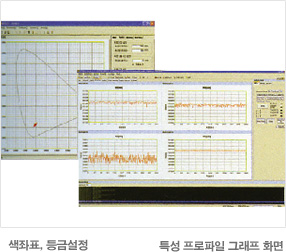

ㆍTest items : Color gamut, flicker rate, response rate (Optional) including luminance,chromatility, color temperature, Peak wavelength, dominant wavelength, Full width half max, Color rendering index, etc

ㆍMeasuring accuracy: wavelength ±3%, chromatility ±0.002

ㆍMeasuring method: Takes 4 minutes for 42" 1000 points including 0.1 second for movement and 0.1 seconds for measurement

ㆍMeasuring method : Measure using spectrophotometer after recognizing location via semi-automatic sample loading and vision

ㆍFeatures : For BLU consisting of RGB LED, it analyzes all optical properties of each LED of RGB and white mixed with three colors by only one measurement (Patent)

- Measure accurate and highly reliable luminance using integrating sphere type input optical system and optical power meter and color correction

- High speed and low noise by using clean room type linear motor

- Optimal for evaluating LED BLU and LED display

ㆍHigh resolution spectrophotometer(TE cooled 2048 CCD Sensor)

ㆍMeasure highly reliable optical properties by using 2" integrating sphere type light receiving head, optical power meter, and spectrometer at the same time

ㆍMeasure accurate and repeatable luminance by correcting color in real time using spectrometer

ㆍStandard measurement solid angle and distance via zoom lense

High speed and low noise linear motor and X-Y-Z robot

ㆍHigh speed and low noise by using clean room type linear motor

ㆍAccurately find and move to measuring location using Vision system to minimize tolerance

ㆍMeasure height of module using height sensor and by moving light receiving head to standard condition location

ㆍLoad various sizes of samples using multi-purpose sample jig

ㆍSemi-auto sample feeding

ㆍBlock light by maintaining measurement dark room

ㆍSW to provide various ranges of information.

ㆍUser is able to select and edit measuring items.

ㆍIntuitive user environment to easily recognize measurement process and result.

(Spectrum, color coordinate, current location, map, etc)

ㆍSeparated display for measurement of R,G,B,W

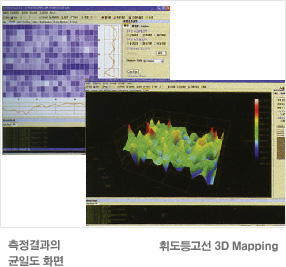

ㆍVarious motion mode: recognize measurement location using vision.

ㆍRecognize measurement location using user's coordinate file.

ㆍRecognize measurement location by user settings. (4, 5, 9, and 16 points, etc)

ㆍMeasurement date is save in informative form (CSV format): Total by each item and spectrum by each sample.

ㆍRGB item in sample: Report generation and save in accordance with user template.

ㆍDisplay overall distribution, set grade, process statistics, and calculate uniformity through map and data screen.

ㆍCIE and KS standard measurement mode and value

ㆍCorrection by using Korea Research Institute of Standards and Science certified correction lamp and LED

ㆍHigh speed and precision Keithley source meter and 2048 CCD sensor

(Select TE Cooled type) : high speed and resolution

ㆍProxy for Korea Research Institute of Standards and Science(KRISS) correction certificate (optional)

ㆍTechnical support and maintenance

- Customer oriented set up, user instruction and development of SW as per customer requirements

- Provide measurement knowledge and information through activities in CEI and photometry club

Service and prompt A/S

| SPECIFICATION | |

|

Spectrometer |

400 to 900nm, TE cooled 2048 CCD array type |

|

Photodiode |

380 to 950nm, 10㎟ Area |

|

Robot System |

X-Y-Z Robot, Linear Motor, Resolution 1㎛ |

|

PD Temperature |

30℃ |

|

Max Sample size |

52 inch |

|

Measurement Speed |

0.1 sec / point |

|

Movement Speed |

0.1 sec / point |

|

Vision system |

CCD camera |

|

Dimension |

3,950mm(W) x 1,660mm(D) x 1,827mm(H) |